Modular pharmacy packaging facilities have become more important than ever as contaminated packaging has been a critical factor in health problems for several pharmaceutical packaging companies. Eliminating sub-micron airborne contamination is really a process of control. These contaminants are generated by people, process, facilities and equipment. They must be continually removed from the air. Starrco’s modular cleanrooms can be set up, sealed, and disinfected easier than any type of conventional construction. This is made possible by the choice of construction materials, and the pre-construction of the modular rooms.

A modular pharmaceutical packaging facility can be configured to exact specifications and interior spaces can be customized and/or expanded as needed to provide more or less space for an individual work station or room. The organization of the modular walls systems permits the preparation of individual prescriptions in the most efficient, cost-effective, as well as sterile manner possible.

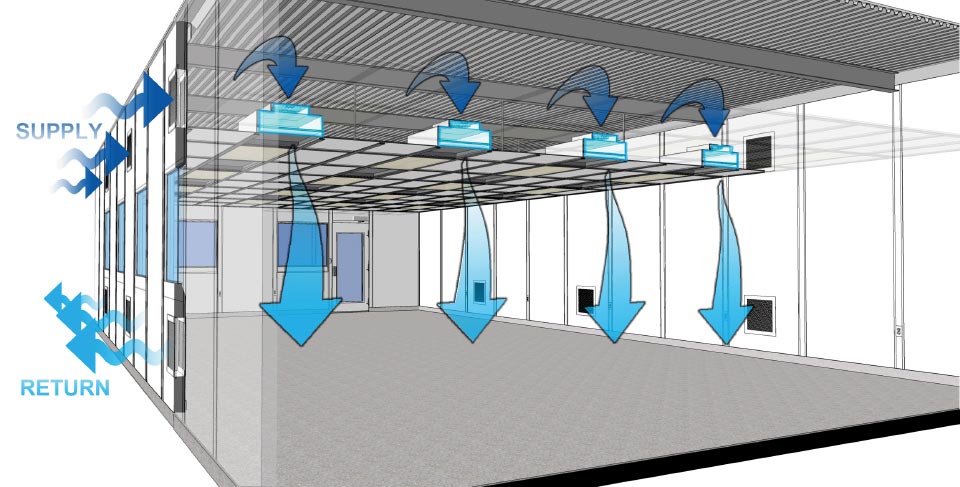

The only way to control contamination is to control the total environment. Air flow rates and direction, pressurization, temperature, humidity and specialized filtration all need to be tightly controlled to contribute to the ultra-pure aseptic high quality of the prescriptions prepared in the modular pharmaceutical packaging facility. Modular cleanrooms are planned and manufactured using strict protocol and methods. All Starrco cleanroom projects start with an on-site needs assessment of location and current facilities. Combined with various air filtration options, a class 10,000 positive pressure can be consistently achieved.

Modular Cleanrooms and Cleanroom Wall Systems

Everything you need to start your modular cleanroom or cleanroom wall systems quote.