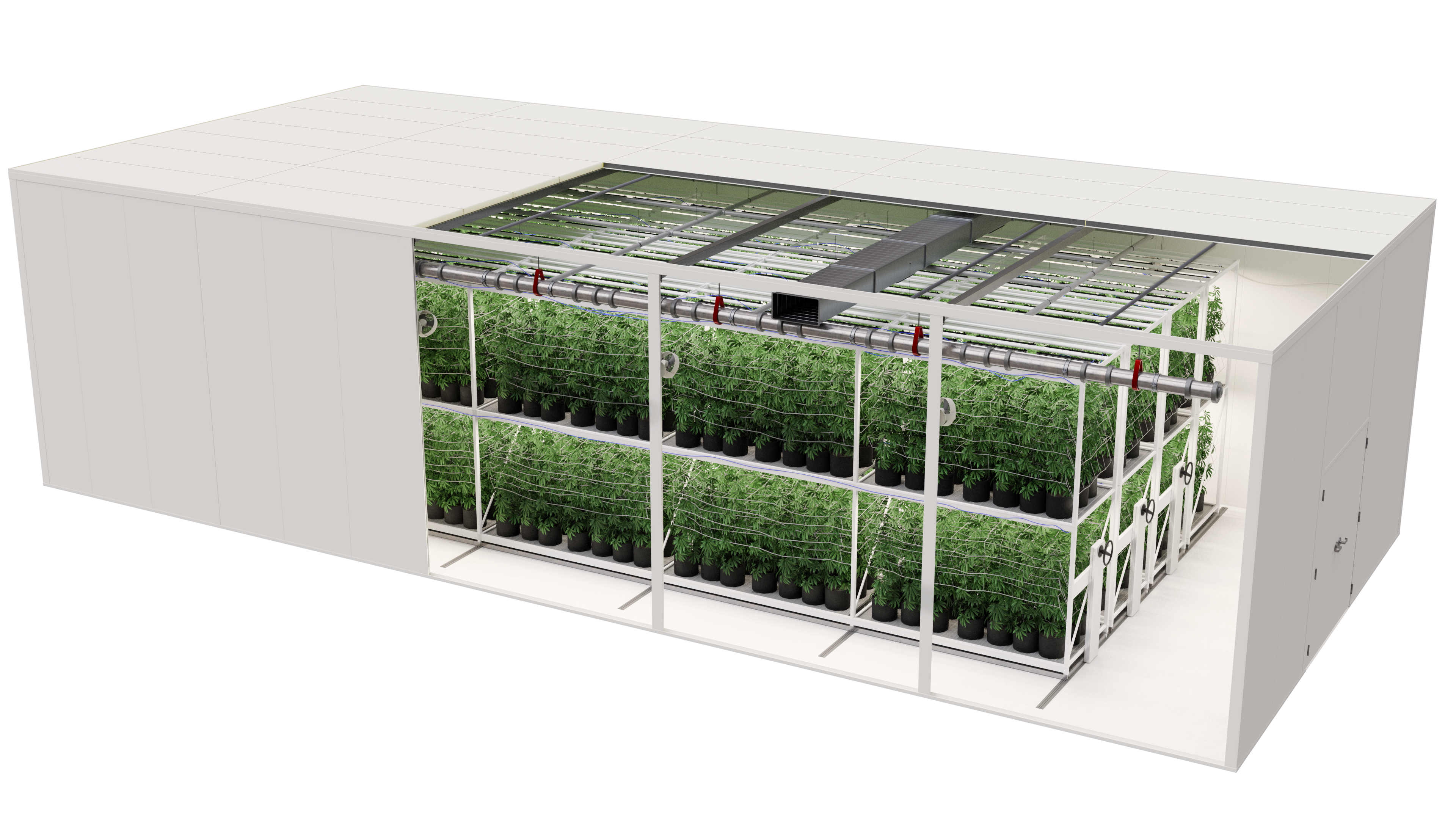

Why Use a Modular Building as Your Indoor Grow Room?

Are you tired of the inconvenience of trying to navigate multiple grow tents? If you’re ready to move to the next level and take control of your production, modular buildings offer the versatility needed to customize a cannabis grow room. These structures also have several logistical advantages that will benefit your business.

Below are four reasons why it makes sense to move your valuable operation to a Starrco modular commercial grow room.

1. Starrco Grow Rooms Provide a Controlled Environment for Cultivation

You can outfit your grow room with climate control features that help you produce consistently healthy plants.

2. Modular Buildings Are Easy to Scale as Your Needs Evolve

Easily increase the size of your grow room by adding new modules or transport the existing modules if you are moving. Starrco modular units make it simple to increase the size of your operation as your business grows.

3. Prefab Units Are a Cost Effective Way to Add New Buildings

Our modular construction system allows us to complete modular cannabis grow rooms up to 75% faster than it would take to build a structure using conventional methods. You can, therefore, use your grow room sooner, eliminating downtime and expediting the return on your investment.

4. Modular Rooms Offer Tax Advantages Over Conventional Buildings

Modular structures fall into the same tax category as other capital equipment. As a result, you can deduct depreciation for your modular grow room over seven years rather than 39 years.