Warehouses are constantly trying to do more with less. One of the biggest challenges they face is a lack of available space — and when you don’t have enough room for storage, material handling, and other pertinent operations, you risk reduced productivity and inhibited profit growth.

If your warehouse is feeling cramped and cluttered, it’s probably not able to operate at maximum efficiency. Luckily, there are plenty of ways you can improve warehouse space utilization and get your facility back up and running at full capacity again. Below, we’ll outline ten of them.

Before you jump into solving your warehouse’s space utilization problem, it’s best to take a step back and really analyze what’s wrong with your current layout. Where is space used inefficiently? How could you reconfigure it for improved utilization? The answers to these questions will help you pinpoint the main contributors to your lack of space, as well as the opportunities you could take advantage of to free it up.

When thinking about warehouse space utilization, consider the current use of your space. What tasks need to be completed in your warehouse by all team members every day? Is there a designated space for every activity? In many warehouses, areas for meetings or other work just naturally evolve, but they may not be the best places for these activities.

For traffic flow, think about the route each worker takes through the warehouse every day. Is the space for each task close to where workers need to go next? If there isn’t a logical flow, your warehouse could be cluttered with traffic. Simply organizing your space according to the natural flow of work can open up room.

If you’re wondering how to improve warehouse space utilization, look up! How much of your facility’s vertical space is available for use? One of the best ways to maximize warehouse space is building up. Whether you choose to build a tall wall system or a two-story configuration, fully utilizing your facility’s vertical space can open up a lot of much-needed room on ground level.

One thing to keep in mind: make sure your vertical build doesn’t interfere with your facility’s fire suppression system — or, if it does, make sure you have a plan for reconfiguring that system so that it can work effectively in the case of an emergency.

If your facility’s layout permits, consider installing a mezzanine for your warehouse’s offices. Modular warehouse mezzanines are another great way to get more out of your facility’s underutilized vertical space, without the hefty costs that come with larger expansion or renovation projects.

By moving main-floor offices up to a mezzanine structure, you’ll free up a ton of space on the ground for manufacturing and production, while also providing office employees workspaces that are more comfortable and conducive to a productive work environment.

When it comes to calculating warehouse space utilization, many companies only consider their ground floor square footage. A mezzanine can increase square feet of space without an expensive construction project that will result in months of downtime.

As an added advantage, mezzanines can encourage safety. Heavy machinery stays on the ground floor, where there is more space around the equipment. Your team can take breaks, eat lunch, hold meetings, and do other activities in the separate area away from heavy equipment.

Often, a congested warehouse leads to an unorganized warehouse. Poor inventory management and overstock issues can result in the same product being located in multiple locations throughout your warehouse, which hurts your efficiency and wastes space. By consolidating all of your products into their own dedicated locations, you’ll experience smoother operations and a more efficient use of space.

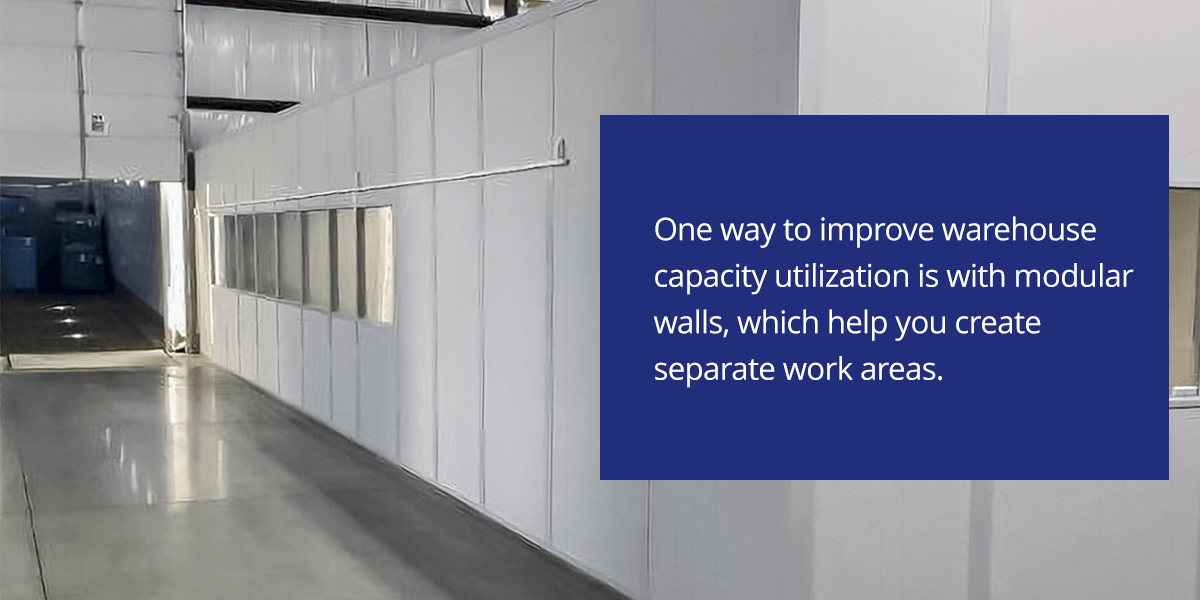

Is your production area taking up too much space? Is there a particular section of your warehouse that always seems to need expanding? Take some time to identify those areas of operation and calculate exactly how much space they need to run safely and efficiently. Once you’ve decided on those numbers, consider putting up some barriers around them so they can’t exceed that allotment. One way to improve warehouse capacity utilization is with modular walls, which help you create separate work areas.

Does your warehouse currently have storage solutions that are either too small or too large for the products they’re intended to hold? This isn’t something to look the other way on, as it’s a huge factor in many warehouses’ ineffective utilization of space.

Try to place unpackaged items in bins and containers that fit their size. Also, consider placing large items on shelving and pallet racks, as unnecessarily large bins take up additional space that you could be using more profitably.

Are there parts or products that sit in your warehouse for extended periods of time? Minimize some of that product so that you’re only keeping what you actually use onsite. Or, try relocating that excess product to a space where it isn’t in the way of your main operations, such as atop a modular warehouse office. You can create modular office solutions that stay on site but don’t require an expensive addition to your warehouse space.

Employees themselves take up space, which is one thing that’s easy for warehouse managers to forget. When the in-plant offices, break rooms, and conference rooms they use are located in various spots around your facility, you’re not making the most efficient use of space. Instead, try consolidating some of your rooms, or moving them all to one central location.

Establishing dedicated areas for employees can also help keep them safe. Instead of walking through potentially hazardous manufacturing and production areas multiple times throughout the day, they can work comfortably and productively in their own space.

Even the smallest details matter when it comes to improving warehouse space utilization. When you’re looking at your aisle widths, they should only use the space that your team actually needs to comfortably walk or drive equipment through. Any additional space can be more efficiently used elsewhere.

If your aisles are wide, consider why. You may have used bigger forklifts or had larger machinery in the past. Make sure your aisles reflect how you do business now.

Your warehouse floor provides a great deal of valuable space. By keeping it clean and clutter-free, you can improve space utilization. Consider placing any less-used materials on top of your modular office to get them off the floor. Or, if you’ve installed a mezzanine, consider placing them below your elevated office.

If you notice clutter building up in one area of the warehouse regularly, take another look at work flows and operations. Are there any inefficiencies that can be addressed? For example, if employees offload materials from the loading dock and pile them nearby instead of taking the shipments to storage, consider whether you need a storage area closer to the loading dock. You may also consider having trolleys or forklifts ready at the loading docks to prevent boxes and other materials from accumulating.

Modular and panelized wall systems are a great solution for optimizing your warehouse space utilization. Whether you want to build vertically, install a mezzanine, or designate a secluded area for your employees, modular wall systems provide the versatility and durability to provide the space you need, when and where you need it. Contact Starrco to learn more about how modular wall systems could benefit your facility.