No one likes the dust and debris caused by construction projects, but in clean manufacturing environments for medical devices, pharmaceutical products, semiconductors, and electronics, construction debris could be hazardous.

Starrco’s pre-engineered modular clean room technology offers a solution.

Clean

Each cleanroom is manufactured at our St. Louis manufacturing facility. That means all the sawing, sanding and other construction mess happens off-site and away from your production facility.

Fast

Starrco’s modular cleanrooms are manufactured and installed 75 percent faster than conventional construction. All the finished pre-engineered construction parts are flat-packed and shipped to your facility ready for install.

Air-tight seal

Walls, floors, and ceilings are precision-cut with smooth edges and precisely mitered joints to ensure a tight, air-leak proof construction and assembly. This facilitates air particle filtration, and the control of air flow, pressure, temperature, and humidity.

Starrco modular cleanrooms are ISO Class 5 to Class 8, USP compliant.

To talk to a modular cleanroom expert about how Starrco custom designs and manufactures cleanrooms call (800) 325-4295.

Download the Starrco Cleanroom Brochure (PDF)

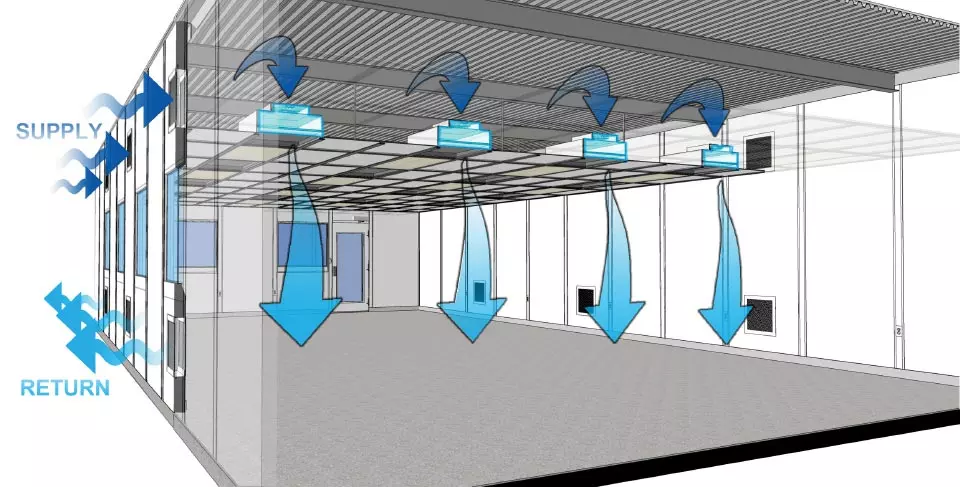

Air-handling and cleaning systems are an important mechanical part of most cleanrooms. To facilitate the efficient working of your air cleaner, our plenums and interior surfaces are made from non-particulate shedding materials such as vinyl, fiberglass, and pre-finished aluminum.

What is a once-through system?

Air is drawn from outside the cleanroom through fan-powered HEPA filters in the ceiling and then expelled outside through wall grills.

What is a recirculating system?

A fan continuously circulates room air via sealed wall plenums so it can be cleaned and filtered by the ceiling-mounted HEPA filter unit.